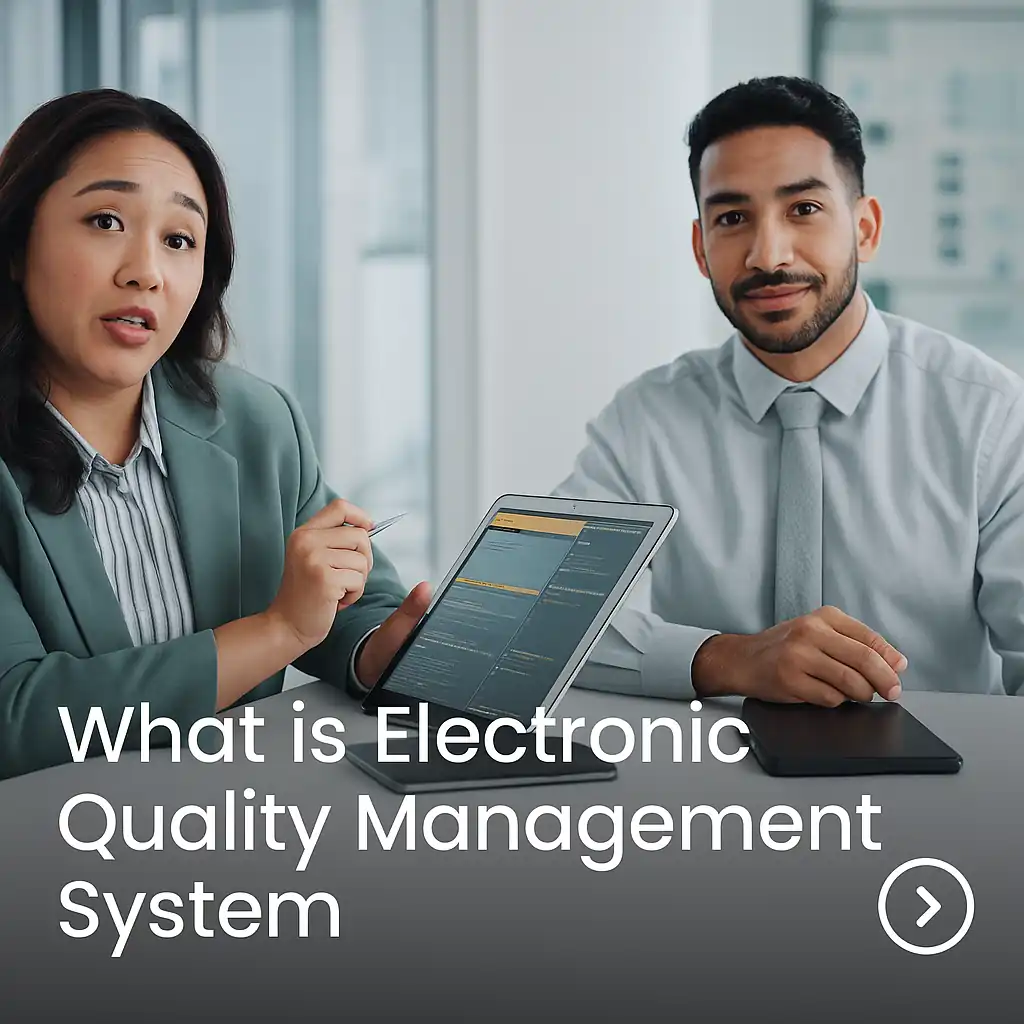

What are the Major Quality Challenges in Medical Devices?

Medical devices are vital components of the healthcare ecosystem. They aid medical professionals to deliver healthcare services successfully in delivering. Today, when the burden of diseases and pandemics is set to go up, medical devices have a greater role in providing infallible diagnoses and treatments.

But this prolific industry faces its own set of major challenges too. Apart from maintaining product quality and navigating through stringent industry regulations, the affordability of these devices proves to be a concerning aspect in influencing their demand in the market. This straight away hampers the revenue and profit margin of the company.

Also, this has led to increased proliferation of counterfeit and cheap devices which might put patients in danger. The only differentiating factor that can make your devices stand out is Quality, something that can’t be achieved through manual methods or spreadsheets, but only through a dedicated Quality Management System for Medical Devices.

A medical device quality management system is a digital tool that helps comply with a structured set of procedures ensuring quality-driven operations throughout the organisation to create safe and effective products.

How does a Quality System for Medical Devices Industry help address these challenges?

Regardless of the industry type, QMS software is now a necessity in this post-pandemic, quality-conscious world. And when it comes to the healthcare industry, a purposeful QMS software for medical devices like QualityPro is the key. It is a complete, web-based regulated system that can handle everything from supplier management, risk management, complaint handling, NC, CAPA, training management, product labelling, and more.

Its personalised cockpit is the single-point access to manage, control, navigate and perform all crucial tasks to rope-in continuous improvements. A wide range of out-of-box reports, that too fully customisable, and interactive dashboards, establish end-to-end visibility at every level of production, ensuring product quality and no reworks.

QualityPro prioritises patient safety in the medical devices industry, providing risk management and aiding in compliance with stringent regulatory standards like Current Good Manufacturing Practices (GMP), 21 CFR Part 11, Annex 11, and ISO: 13485.

Your path to better quality management starts here

Features of QMS for Medial Devices

Efficiently handle non-conformance (NC) issues like deviation from established procedures, shortcoming in program implementation, etc. Perform root cause analysis and apply corrective actions to avoid recurrence…Read More

Effectively deal with complaints like inappropriate execution of plan, gaps in communication, etc. Track the status and resolution of such complaints to establish positive relations with stakeholders…Read More

Identify the learning gaps like procedural knowledge, legal requirements knowledge, communication lacunas etc. and schedule trainings for employees. Track and store training progress of staff for future reference...Read More

Smoothly incorporate change in the organisation without disturbing day-to-day chores. Establish a proper workflow for documenting changes, update the concerned, review its impact and manage every step of the change control process...Read More

Manage organisational documents like procedures, certificates, SOPs, fund raising documents etc. Collaborate simultaneously on the same document version, enhancing teamwork….Read More

Manage various risks like financial risk, cybersecurity risk, operational risk, governance risk, etc., associated with medical device manufacturing organisations. Mitigate probable risk and drive continuous improvement across the organisation…Read more

Make organisation audit ready, be it internal or external, by ensuring compliance with various regulations. Conduct mock audits and find the gaps to fill during real audits and prevent penalties and reputational dents...Read More

Don’t wait! See how various organisations streamlined quality with QualityPro

Features of QMS Software for Medical Device

Efficiently handle non-conformance (NC) issues like deviation from established procedures, shortcoming in program implementation, etc. Perform root cause analysis and apply corrective actions to avoid recurrence…Read More

Effectively deal with complaints like inappropriate execution of plan, gaps in communication, etc. Track the status and resolution of such complaints to establish positive relations with stakeholders…Read More

Identify the learning gaps like procedural knowledge, legal requirements knowledge, communication lacunas etc. and schedule trainings for employees. Track and store training progress of staff for future reference...Read More

Smoothly incorporate change in the organisation without disturbing day-to-day chores. Establish a proper workflow for documenting changes, update the concerned, review its impact and manage every step of the change control process...Read More

Manage organisational documents like procedures, certificates, SOPs, fund raising documents etc. Collaborate simultaneously on the same document version, enhancing teamwork….Read More

Manage various risks like financial risk, cybersecurity risk, operational risk, governance risk, etc., associated with medical device manufacturing organisations. Mitigate probable risk and drive continuous improvement across the organisation…Read more

Make organisation audit ready, be it internal or external, by ensuring compliance with various regulations. Conduct mock audits and find the gaps to fill during real audits and prevent penalties and reputational dents...Read More

Benefits of Medical Device Quality Management System

- Promotes effective and faster execution of processes

- Increases customer satisfaction with precise manufacturing

- Elevates brand value by adhering to safety standards

- Traceability to reduce waste

- Increases efficiency by improving supply chain performance

- Enhances safety by reducing risks

- Growth in new customers, and increased retention by improving customer satisfaction

- Competitive advantage over the competition

- Improved decision-making process

Trusted by Industry Leaders

“Just one click, and you are one step closer to a transformation”

Know right away how QualityPro can transform your business

FAQs

A Medical Device Quality Management System (QMS) Software is a purpose-built digital solution that enables medical device manufacturers to ensure alignment with stringent regulatory frameworks. It facilitates end-to-end quality assurance by automating critical functions such as document control, risk management, Corrective and Preventive Actions (CAPA), and internal and external audits. This comprehensive platform supports the design, development, manufacturing, and post-market surveillance phases, ensuring the safety, efficacy, and regulatory compliance of medical devices.

The medical devices sector is governed by complex and evolving regulations such as ISO 13485, FDA 21 CFR Part 820, and EU MDR. A robust QMS software for medical devices enables manufacturers to digitise and harmonise quality operations, ensuring consistency and compliance across the entire product lifecycle. By centralising processes, the software mitigates the risk of non-conformance, enhances traceability, and supports a culture of continuous improvement—all while reducing manual interventions and driving operational efficiency.

A Medical Device Quality Management System Software provides built-in capabilities tailored to meet international regulatory obligations. It ensures that quality processes are aligned with the specific requirements of regulatory bodies, thereby enabling manufacturers to demonstrate inspection readiness and maintain conformity throughout the product lifecycle.

A Quality Management System for medical devices fosters product quality through enforced process control, standard operating procedures (SOPs), and real-time quality data analytics. By reducing the reliance on manual processes, the system minimises human error and supports early detection of nonconformities. Features such as closed-loop CAPA, nonconformance management, and change control ensure that issues are addressed proactively—enhancing device performance, reliability, and ultimately patient safety.

Absolutely. A Medical Device Quality Management System, such as QualityPro, significantly improves audit readiness by maintaining a secure, centralised repository of all quality records, including validation protocols, training logs, etc. Automated reporting and advanced search capabilities make it easy to retrieve documentation during regulatory inspections, ISO audits reducing audit preparation time and ensuring uninterrupted compliance.

A Quality Management System in the medical devices industry enhances operational efficiency by automating core quality processes such as change management, deviation reporting, and training compliance. By reducing administrative overhead and facilitating cross-functional collaboration, the software enables quality, regulatory, and engineering teams to work more cohesively.

Document control in a Medical Device Quality Management System Software is managed through a structured framework that includes version control, access permissions, and review and approval workflows. The system ensures that only authorised users can view, edit, or approve quality-critical documentation, such as technical files, validation reports, and regulatory submissions. This helps maintain an accurate and auditable record of changes.