What are the Major Quality Challenges in Rubber Industry ?

Rubber, due to its unique properties, has become a go-to-material for countless products that touch our daily lives. From the tyres on our vehicles, to the numerous rubber-based components used in industrial machineries, it is remarkably versatile and indispensable.

Among its myriad applications, perhaps the most well-known use of rubber lies in the manufacturing of automobile tyres. Its ability to absorb shocks and maintain durability under adverse conditions makes rubber a safer option on the roads.

However, at the core of tyre manufacturing rests a landscape full of intricate challenges. Fluctuating raw materials costs, supply chain disruptions, and fostering innovation are the foremost challenges manufacturers encounter. In addition, the intensifying global competition, and the need to cater to a diverse array of consumer preferences, adds up to their complexity.

?

Furthermore, the tyre manufacturing process itself involves numerous energy-intensive procedures and the utilisation of around 30 distinctive ingredients, including various toxic chemical compounds. These aspects collectively cast a shadow of environmental & health concerns over the industry.

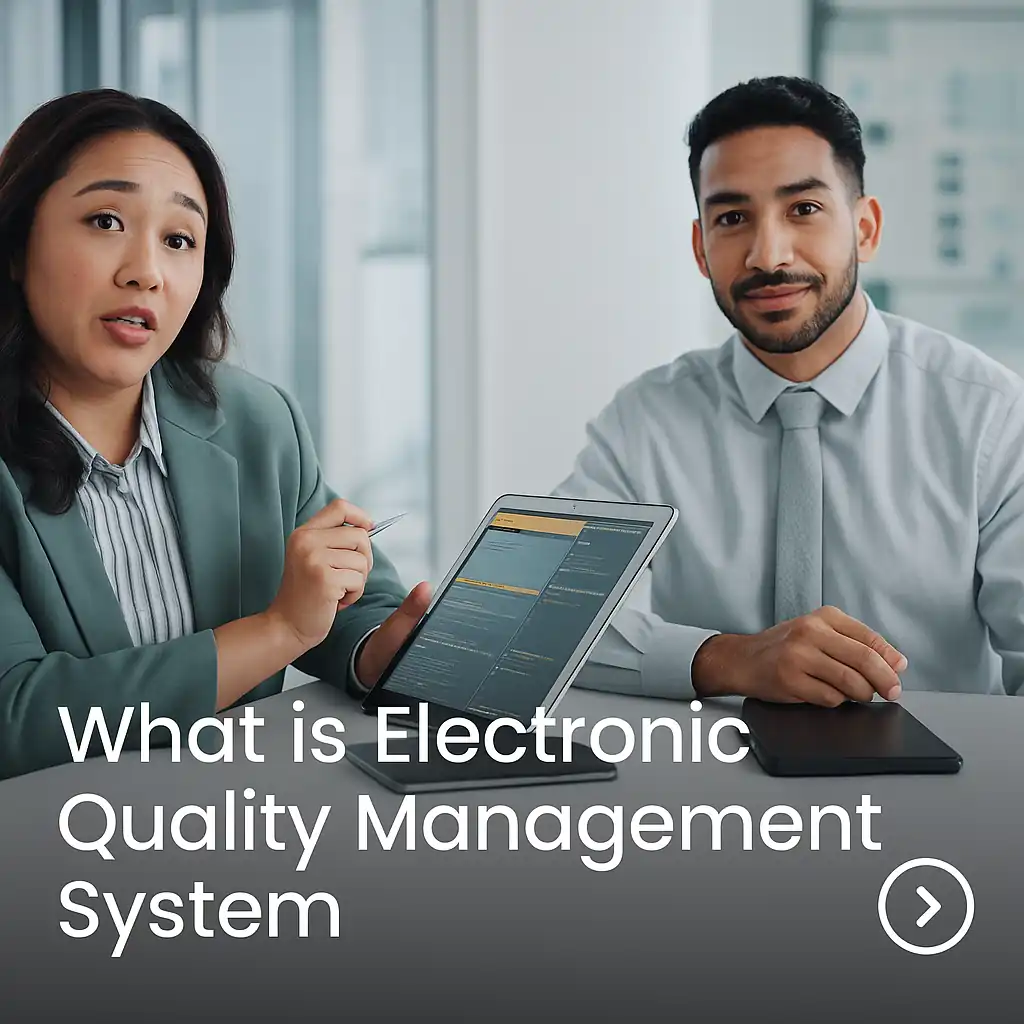

In light of these challenges, manufacturers are compelled to produce products that comply with the various safety and regulatory standards of the industry. But, old and paper-based techniques to ensure quality management will prove obsolete in this fast-moving world.

Thus, in response, organisations must have a quality system i.e. a QMS for Rubber Manufacturing in place which helps them maintain consistency in their operations and ensure unwavering quality of their products. One such QMS system is QualityPro.

This thoughtfully created system with its comprehensive modules ensures that the organisations follow the standard procedures and produce quality products.

Your path to better quality management starts here

Features of QMS Software for Rubber and Tyre Industry

Efficiently handle non-conformance (NC) issues like deviation from established procedures, shortcoming in program implementation, etc. Perform root cause analysis and apply corrective actions to avoid recurrence…Read More

Effectively deal with complaints like inappropriate execution of plan, gaps in communication, etc. Track the status and resolution of such complaints to establish positive relations with stakeholders…Read More

Identify the learning gaps like procedural knowledge, legal requirements knowledge, communication lacunas etc. and schedule trainings for employees. Track and store training progress of staff for future reference...Read More

Smoothly incorporate change in the organization without disturbing day-to-day chores. Establish a proper workflow for documenting changes, update the concerned, review its impact and manage every step of the change control process...Read More

Manage organisational documents like procedures, certificates, SOPs, fund raising documents etc. Collaborate simultaneously on the same document version, enhancing teamwork….Read More

Manage various risks like financial risk, cybersecurity risk, operational risk, governance risk, etc., associated with rubber and tyre manufacturing organisations. Mitigate probable risk and drive continuous improvement across the organisation…Read more

Make organisation audit ready, be it internal or external, by ensuring compliance with various regulations. Conduct mock audits and find the gaps to fill during real audits and prevent penalties and reputational dents...Read More

Don’t wait! See how various organisations streamlined quality with QualityPro

Features of QMS Software for Rubber Industry

Efficiently handle non-conformance (NC) issues like deviation from established procedures, shortcoming in program implementation, etc. Perform root cause analysis and apply corrective actions to avoid recurrence…Read More

Effectively deal with complaints like inappropriate execution of plan, gaps in communication, etc. Track the status and resolution of such complaints to establish positive relations with stakeholders…Read More

Identify the learning gaps like procedural knowledge, legal requirements knowledge, communication lacunas etc. and schedule trainings for employees. Track and store training progress of staff for future reference...Read More

Smoothly incorporate change in the organization without disturbing day-to-day chores. Establish a proper workflow for documenting changes, update the concerned, review its impact and manage every step of the change control process...Read More

Manage organisational documents like procedures, certificates, SOPs, fund raising documents etc. Collaborate simultaneously on the same document version, enhancing teamwork….Read More

Manage various risks like financial risk, cybersecurity risk, operational risk, governance risk, etc., associated with rubber and tyre manufacturing organisations. Mitigate probable risk and drive continuous improvement across the organisation…Read more

Make organisation audit ready, be it internal or external, by ensuring compliance with various regulations. Conduct mock audits and find the gaps to fill during real audits and prevent penalties and reputational dents...Read More

Benefits of QMS for Rubber and Tyre Manufacturing

- Facilitates faster and effective execution of processes

- Helps maintain consistent product quality and adheres to industry standards & specifications

- Minimises the risk of defects, leading to reduced errors, rework, and waste

- Increases efficiency through standardisation of processes

- Lowers the production costs significantly

- Enhances safety across the entire organisation

- Helps make informed decisions based on data and insights

Trusted by Industry Leaders

“Just one click, and you are one step closer to a transformation”

Know right away how QualityPro can transform your business

FAQs

A Quality Management System (QMS) for rubber manufacturing is a structured framework designed to ensure product integrity, regulatory compliance, and process efficiency throughout the production of rubber compounds, tyres, and tubes. It supports adherence to global standards such as IATF 16949 and ISO 9001, minimises production variability, enhances traceability across the rubber compounding, curing, and vulcanisation stages, and ultimately drives consistent output in high-demand applications such as passenger vehicle tyres, OTR tyres, and industrial rubber goods.

QMS software for the rubber industry is essential in maintaining uniformity across critical processes such as rubber mixing, extrusion, and moulding. By digitising quality workflows, it enables manufacturers to comply with industry regulations, identify defects in early production phases, and maintain specification tolerances. The software aids in reducing scrap rates and supports compliance with REACH, RoHS, and environmental health and safety (EHS) standards relevant to rubber production.

In tyre manufacturing, a QMS ensures that each phase—from raw material inspection (e.g., carbon black, natural rubber, synthetic rubber) to green tyre assembly and final curing—meets stringent quality benchmarks. Through the integration of digital quality software for tyre production, manufacturers can monitor defect codes, perform in-line testing, and manage corrective action workflows in real time. This results in higher product reliability, fewer non-conformances, and improved customer satisfaction.

A robust QMS tailored for the rubber and tyre sector typically includes:

- Process Control & Monitoring – Ensures alignment with regulatory and customer-specific requirements through real-time SPC (Statistical Process Control) and control plan execution.

- Document Management – Centralises and maintains version control of SOPs, work instructions, and compliance records.

- Non-Conformance Management – Facilitates timely identification, documentation, and resolution of quality issues using defect tracking matrices.

- Inspection & Testing – Digitises in-process and final inspections, including tensile strength, elongation at break, and hardness testing, ensuring data accuracy and compliance.

Absolutely. Quality management software for the rubber industry, like QualityPro, plays a pivotal role in reducing defects by enabling real-time process analytics, early detection of out-of-spec conditions, and swift implementation of corrective measures. It supports FMEA (Failure Mode and Effects Analysis), ensuring potential failure points in rubber formulation or tyre construction are proactively addressed. This minimises reworks, optimises resource usage, and ensures consistent tread performance, tyre uniformity, and durability.

Digital quality software for tyre production empowers manufacturers of tyres and inner tubes to automate quality checks, manage production part approval process documentation, and maintain compliance with automotive OEM standards. By digitising inspection protocols and linking them to machine-level data (e.g., cure press parameters, build uniformity, balancing results), the software reduces manual errors and accelerates first-time-right production, enhancing reliability and safety of the final product.

A QMS for rubber manufacturing promotes continuous improvement by leveraging real-time KPI dashboards, trend analysis, and audit management tools to pinpoint inefficiencies and quality bottlenecks. It empowers quality teams to implement Lean and Six Sigma methodologies across compound development, milling, and tyre assembly, fostering a culture of operational excellence. Insights drawn from QMS data help streamline change management and ensure ongoing product and process enhancements.