Every day, hundreds of thousands of vehicles move through the streets, each running on multiple tyres. And while they may go largely unnoticed, it remains a fact that they are an essential part of the urban landscape. But this isn’t just about the vehicles or their tyres. We’re looking at something deeper.

So, every tyre that meets the road, or for that matter, every seal that keeps an engine leak-free, and every gasket holding complex machinery together, is the result of meticulous precision. Their flawless performance is proof that the rubber manufacturer left no room for guesswork.

Whether it’s tyres or any other product, wise rubber manufacturers understand that precision is non-negotiable in their industry, and that even a slight inconsistency in the manufacturing process can lead to cracked tyres, leaking systems, or failed safety tests.

And when such failures occur, the consequences can go far beyond scrap piles. They may result in massive recalls, regulatory fines, and considerable damage to brand trust.

Navigating the Complexities of Rubber and Tyre Manufacturing

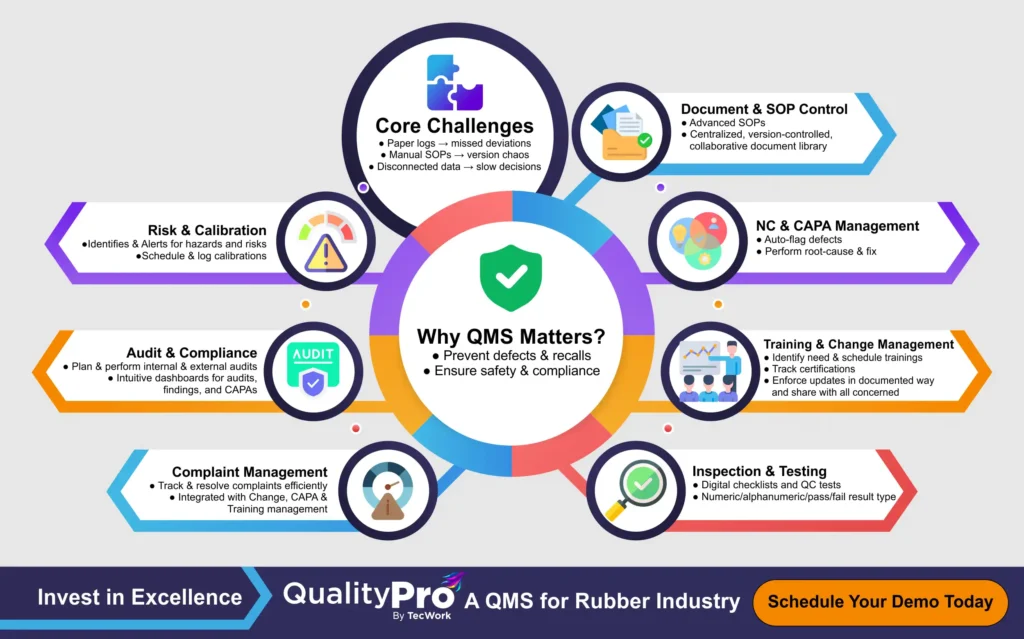

It isn’t just about precision that we are talking about here, as rubber manufacturers face challenges that go beyond material precision. When they run their operations manually, inspections and paper-based records find it hard to keep up with real-time production.

This lets the defects slip through, leading to costly rework and scrap. This way, consistency suffers in the absence of automated quality management in rubber and tyre manufacturing.

Then there are traceability and efficiency risks for the rubber manufacturers. Resorting to traditional logs hinders their accountability and slows down root-cause analysis and corrective actions.

Moreover, disconnected data delays insights, thereby preventing timely interventions, whereas manual increases the risk of nonconformance, making efficient training and change control essential.

There are regulatory challenges as well. Meeting ever-tighter tolerances, constantly evolving compounds, and exacting ISO 9001, IATF 16949 for automotive, REACH, RoHS, and EHS standards demands more than spreadsheets and clipboard inspections.

Quality Management Systems: The Backbone of Rubber Manufacturing

Under these circumstances, rubber manufacturers require a specialized Quality Management System designed for the rubber industry; a solution that brings real-time oversight, automated compliance, and robust quality control in rubber manufacturing to every stage of production.

Having one such software for quality management by their side gives rubber manufacturers a definite edge, allowing them to ensure product integrity, regulatory adherence, and ultimately, consumer trust. In fact, it is only then that they can achieve true quality management in rubber processing and keep their products, as well as reputation, rolling smoothly.

This blog highlights key features of a QMS to explain how rubber manufacturers can overcome their business hurdles and set new quality benchmarks by having a solid QMS at their disposal. In short, this blog explains why there’s a pressing need for rubber manufacturers to invest in QMS software. Read on.

Unlike generic tools, a QMS for tyre and rubber production addresses unique challenges such as batch management, curing profiles, test methods (hardness, tensile strength), and calibration needs. Let’s understand how:

1. Document Management & SOP Control:

A robust QMS software centralizes all quality documents, including the SOPs, work instructions, and test methods, while enforcing version control. It also facilitates automated workflows, which in turn ensures that only the latest procedures are accessible on the shop floor, thereby reducing nonconformities. So, investing in sound QMS software let’s the rubber manufacturers say goodbye to outdated manuals.

2. Non-Conformance (NC) & Corrective and Preventive Action (CAPA):

In rubber manufacturing, defects like off-spec hardness or improper mixing ratios trigger NC alerts. And by having a specialized QMS, tyre manufacturers can log these non-conformances, initiate root-cause investigations, and drive CAPA workflows with approval loops and effectiveness checks.

This systematic approach fosters continuous improvement in both product quality and process reliability.

3. Training Management:

Ensuring a skilled workforce is absolutely essential for quality management in rubber manufacturing. And a QMS system with a dedicated training management does exactly what is needed.

This module schedules training sessions, tracks certifications, and sends notifications for recertification, thereby reducing chances of human error in critical operations. Its presence in the module suite is enough for the rubber manufacturers to invest in effective QMS software.

4. Change Management:

In the ever-evolving rubber market, formulation alterations or equipment upgrades are quite frequent. That’s where a QMS software’s Change Management Module comes in handy, as it logs updates to SOPs, compounds, and process parameters.

Besides, it also enforces digital approval workflows, ensuring compliance with ISO 9001 while adapting swiftly to changing customer and regulatory demands.

5. Complaint Management:

In any industry, customer feedback holds immense value. And, rubber manufacturing industry is no different. Say, when the manufacturers get reports of premature wear or squealing tyres, they need to act fast to resolve them.

By having an integrated complaint management module in their QMS, rubber manufacturers can log, assess, and investigate the complaints alongside the CAPA processes. This holistic view strengthens quality management in rubber processing and helps build consumer trust.

6. Audit & Compliance

Right from internal audits to third-party assessments (IATF 16949, ISO 9001, REACH, RoHS, EHS), an effective QMS software consolidates audit trails and corrective action records, and facilitates achieving compliance- all on one single platform.

Its real-time dashboards highlight compliance status and readiness for external audits, eliminating scramble mode before every review. By automating compliance tracking and generating reports, it minimizes audit stress and keeps your business fully compliant.

7. Inspection & Testing Management

Rubber products need to undergo multiple quality checks, from incoming raw material inspection to in-process compounding and finished goods’ testing.

A QMS software’s Inspection module allows maintaining QC test items and defining tests, and embeds digital inspection checklists, test plans, and automated pass/fail notifications within the production workflow.

This instant visibility into test results prevents off-spec batches from progressing, thus reinforcing the value of investing in a QMS.

8. Risk & Calibration Management

A proactive Risk Management module of a purpose-built QMS software flags potential hazards, such as mixing variances or equipment malfunctions, before they snowball into full-scale non-conformances.

Simultaneously, its Calibration Management Software schedules and records calibration activities for hardness testers, viscometers, and curing presses, among other things, maintaining measurement accuracy that’s critical for quality management in rubber manufacturing.

Wrapping Up

Rubber manufacturing businesses like yours face relentless pressure from all sides. This includes rising customer expectations, stringent regulations, and the constant demand for innovation, to name a few.

Investing in specialized QMS software such as QualityPro by TecWork transforms quality management in rubber manufacturing from reactive firefighting to proactive excellence.

By having it at your disposal, you can ensure that every batch meets the highest benchmarks of quality management in rubber and tyre processing, while enjoying its other advantages such as real-time visibility, streamlined processes, and steadfast compliance, for your business.

So, what are you waiting for? Don’t let your business depend on outdated, paper-bound methods. Explore QualityPro, TecWork’s dedicated QMS solution for rubber industry, and discover how by investing in it, you can safeguard your products, reputation, and bottom line. Contact us to schedule a demo, today.