Why does QMS Software Matter in Automotive Manufacturing?

Imagine the airbags don’t function properly during an emergency, or the car doesn’t stop even after the brakes were applied, or the scooter has skids on the roads? Scary, isn’t it?

These can only lead to misfortunes like road accidents and, have the potential to cause major injuries or even deaths.

You don’t want this to be the fate of your customers and also of your business Automotive Industry carriers on its shoulder the responsibility of the lives of their customers and thus should deliver best quality vehicles. One small design error might result in major blunders, which no one can afford, neither the customer, nor the manufacturer. So, Quality should be the prime focus for all automotive businesses.

Introduction

Be it a car, traveling bus, goods carriers, trucks or any other vehicle, the transportation medium has now evolved into a sustainable system that ensures smooth journeys, entertains passengers, connects with traffic services, and provides SOS help in case of emergency.

That said, this evolution has made quality, more important than ever before, manufacturers perform multiple tests on their before sending it to the market.

The makers must ensure that their products are as per the standards, follow govt & road norms and are fit to use. And, in order to achieve this, automotive manufacturers must deploy a powerful automotive quality system in their businesses.

QMS systems for automotive industry can streamline quality processes, and track and resolve product issues before they are delivered to the market. This solution also helps in meeting compliance, adapting to industries’ best practices, and focusing on gaining operational excellence.

Gartner defines quality management system software as “the business information management system that manages quality policies and standard operating procedures (SOPs). This includes customer requirements, quality documents, ISO requirements, manufacturing capabilities, robust design, auditing procedures and protocols, nonconformance/risk management activities, testing criteria, industry-specific regulations and much more.”

Ref: https://www.gartner.com/reviews/market/quality-management-system-software

Quality Management systems for Automotive Manufacturers

Quality is characterized in the automotive industry by high production rates and low failure tolerance. Even if quality has different limitations, the influence on people’s lives justifies the automotive industry’s constant emphasis on quality.

Based on customer demands and legal constraints, quality management has grown into a key strategy for many industries, including the automotive sector. Before a company makes any product available for consumer use, quality checks, audits, and ISO standard compliance should be thoroughly checked.

It makes sure that you are using the proper procedures and workflows to achieve customer satisfaction. Automotive quality management solutions can help you to prevent quality issues from occurring and enable continual improvement of the business.

How Quality Management Systems matter in automotive Suppliers and Manufacturers

From safety inspections to compliance audits, the automotive sector needs to achieve certification in specialized ISO standards as well as quality standards. A well-managed QMS is therefore something that can’t be skipped.

Quality in the product, quality in manufacturing, and quality in ownership—are the foundation of automotive quality.

Quality in product means the functional benefits of the particular produced item, while quality in production means consistent production standards and quality in ownership relates to customer satisfaction. And so, automotive manufacturers must put a quality management system in place to ensure regulatory compliance and operational excellence. Companies can plan, design, implement, and control business processes throughout the supply chain by automating their quality procedures with a QMS.

Here are some important aspects that can justify the importance of automotive quality management software:

- To efficiently capture, manage and track non-conformance issues and perform root cause analysis to never let that issue happen again.

- To identify product quality issues, take containment actions, mitigate recurrence & verify the effectiveness of root cause elimination.

- To investigate, track and resolve quality-related customer complaints right from identification to resolution

- To automate the training process & store the important curriculums and schedules centrally.

- To establish a proper document workflow, automate changes (if done), and secure them with authenticated access.

- To store, create, track, retrieve, secure & manage organizational documents.

- To stay compliant with all the crucial norms and manage potential issues using automated alerts.

- To assess risks and analyze their impact so that measures could be taken to mitigate them.

- To automate & streamline the process of planning, scheduling & conducting audits.

How to Ensure Proper Quality Controls in Automotive Industry?

Quality needs to be firmly rooted in automotive manufacturing and good QMS software must ensure that quality is maintained at all levels. With a proper automotive QMS in place, the consistency of the vehicle parts and automobiles produced is ensured. All parts manufactured are also guaranteed to be par with the standards. This leads to a more efficient manufacturing line, which is more resource effective.

Ensuring proper quality controls in the automotive industry would require you to-

- Streamline supplier quality-related process

Quality control in the automotive industry starts with the kind of raw material procured from the supplier. To make sure that you are doing business with the right vendors, their certifications and other details must be checked and stored in a systematic document format. And for this, a quality management solution can help by suggesting buying only from the certified vendors. It even alerts when a vendor certification is nearing expiry.. It also improves collaboration and communication with the suppliers, strengthening business relationships.

By analyzing and optimizing supplier-related procedures, the automotive industry may achieve operational excellence and respond to market changes much more swiftly.

- Establish an effective NC/CAPA Management System

Nonconformance are common in manufacturing, but they aren’t acceptable. So, you must have a well-defined CAPA management process to manage defects and deviations that could impact product quality. An effective NC/CAPA management solution can help automotive companies to identify the root cause of the problem efficiently and eliminate them, so they do not reoccur. Such system has a reliable for tracking and reporting non-conformances. QMS system with NC/CAPA helps in determining all non-conformances with the necessary information.

QMS software for automotive also gives you more visibility through the product failure trends and develop an action plan accordingly. By establishing an effective CAPA management system, it can help you take a holistic approach to prevent and correct systemic issues.

- Simplify Parts and Component Inspections

Because of the wide variety of products, production methods, and testing cases, maintaining consistency in the automotive industry is challenging. However, robust Inspection Management software can be helpful in streamlining the incoming, in-process, and outgoing inspection processes. It also ensures the quality of incoming materials by standardizing sampling plans across different components and products. You must ensure that the QMS software they use has an intuitive and customizable interface in order to have simple and efficient inspections done.

Companies in the automotive industry that standardize inspection procedures are more likely to avoid poor outcomes and needless expenditures associated with a product recall.

- Handle Complaints Effectively

An efficient process for managing complaints must be put in place for automotive companies if they intend to keep their clientele happy and loyal. Automotive QMS manages and performs the full Complaint lifecycle, which includes identifying the issue, conducting a root cause investigation, instantly answering consumer inquiries, and initiating both internal and external corrective and preventative actions.

Automotive companies that have a standardized complaints module in their QMS systems are likely to build lasting business relationships with their customers, suppliers, and stakeholders.

- Perform periodic audits

Companies need Audit Management to carry out and manage external and internal audits and maintain quality standards in the automobile industry. To prepare firms for audits, it is crucial to select a system that offers IATF 16949 compliance. You should have more freedom to carefully prepare for yearly, biennial, quarterly, and ad hoc audits with the QMS software. And so, make sure the quality management software you select includes customizable workflows to easily manage various audit types.

- Provide Best-Practices Training to Your Workforce

Training is an essential part of staying on top of all certifications that the organization requires. An effective training management system identifies training needs within different departments and monitors the results of all training, including documents, read and signed-off assessments, and instructor-led training. An organization can also release certificates based on employee performance. Automotive companies should emphasize employee competency through effective training programs through a Quality Management System to ensure that they follow best practices to achieve the organization’s quality objectives.

- Manage Controlled Documents and their Changes

Automotive companies can put their trust in Document Management System of a QMS to manage all their business-critical documents from creation to approval, publishing to archiving and removing them permanently. With the QMS solution, you can schedule approvals, archival, and document management well in advance. Users and organizations can work collectively to review documents and notify through alerts when the changes are done.

QualityMaster for Automotive Industries: One-Stop Solution to manage all your commute vehicles

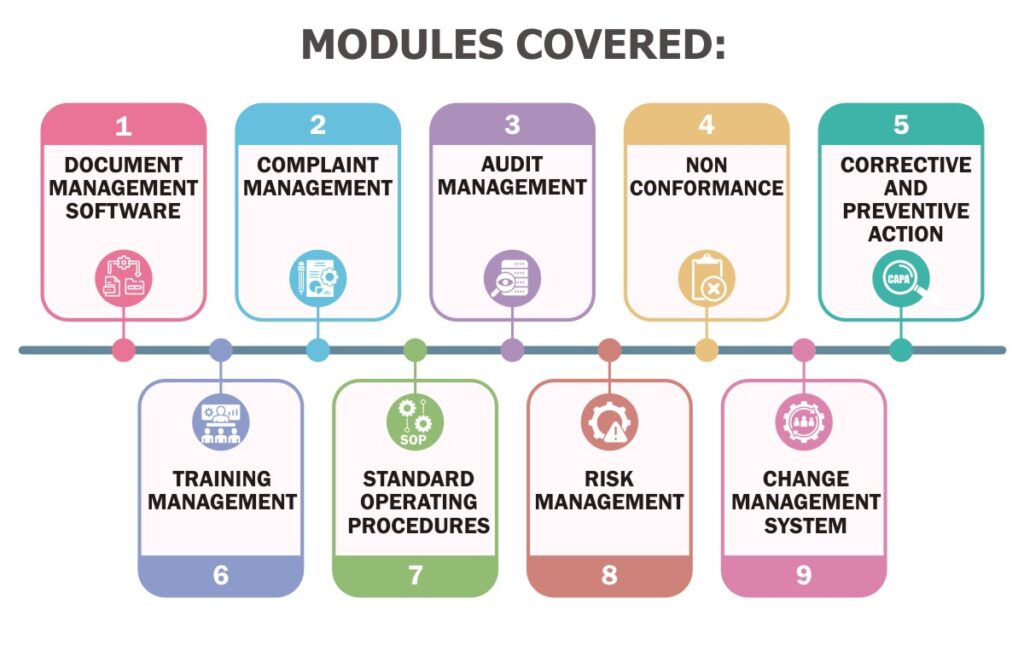

Manufacturers can maintain production efficiency and profitability while achieving the highest levels of quality with QualityMaster. It is a cutting-edge quality management software for the automotive industry. hosting a variety of features like Change Management, Complaint Management, NC, CAPA, Training Management, Compliance Management, Risk Management, and more. –

Manufacturers can keep up with the most recent production definitions in accordance with ISO, IATF, and governmental regulations with the help of QualityMaster. Moreover, the much-needed responsiveness to customer queries and complaints is just a click apart. The user gets a personalized cockpit to optimize operations for ongoing improvements. It even makes it easier for manufacturers to issue SOPs, carry out safety inspections, and raise alarms right away in the event of deviations. It makes sure that industry best practices are followed in order to assist vehicle manufacturers in maintaining compliance and obtaining the necessary level of consistency and product quality.

Final Thoughts

Thinking about elevating your quality processes and streamlining all the activities, then visit us.