According to a report, the global quality management software market size was valued at USD 9.37 billion in 2022 and is expected to record a compound annual growth rate (CAGR) of 10.6% from 2023 to 2030.

The figures clearly indicate that due to the growing consumer awareness and demand for quality, more and more manufacturers are turning towards adopting this digital approach of maintaining “Quality” in their products.

The QMS Software market saw a slump in its growth, during pandemic, owing to financial restrictions. But, since the market has recovered to its original strength, organizations are more vigilant to serve the quality-seeking customers just what they need.

Moreover, the manufacturers are even focused on enhancing sustainability practices into their routine operations with a supreme goal of reducing waste and carbon footprint.

These and many such factors have set the base for QMS trends that will rule 2024.

So, the quality management strategy of the manufacturers seeking one should be based on the trends that are mentioned ahead in this blog.

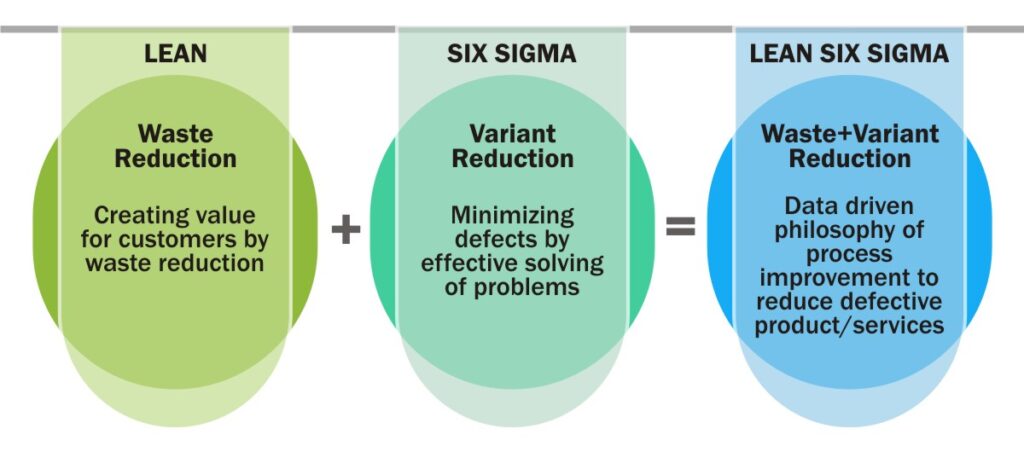

Increased Adoption of Lean Six Sigma-

The combination of these two fundamentally sound methodologies- Lean Manufacturing and Six Sigma, is taking a front stage these days.

Reason? It provides a streamlined framework to businesses to incorporate an improvement strategy focusing on managing

1. The flow of materials and crucial information between the processes,

2. Minimizing waste,

3. Addressing and removing the no-value-adding tasks.

This in turn helps bypass challenges like meeting customer expectations, cutting costs pressures, improving profits, and reducing lead times.

Aren’t these reasons enough to crown adoption of lean six sigma a top QMS trend of 2024.

Growing Cloud Technology-

Businesses, to excel today must have flexibility, scalability, and transparency.

Holding on to the on-premises software solutions with huge infrastructure maintenance cost, slow performance, pending updates, location-dependent services, and much more, could be detrimental.

On the contrary, having remote and faster accessibility to all data, ability to collaborate multi-locations and multi-sites, scalability to new needs and norms and such capabilities ensure business not just survive but thrive in this digital world.

These capabilities are offered by Cloud-Solutions, and this makes it yet another top trend of 2024.

Increased Focus on Supplier Management-

Poor supplier performance impacts an organization’s product quality, finances, time, customer base, brand image in the form of lost sales, costly recalls, penalties for non-conformance, etc.

Thus, upgrading and maintaining the supplier quality—by partnering the suppliers capable of meeting regulatory & safety standards, would be an unavoidable trend to eye on.

Managing Cyber Security Risks-

In the era of tech dominance, cyber risks have become a major concern, specifically for the manufacturers that are data-dependent.

Hence, enhancing security to safeguard trade secrets like formulas/recipes, crucial documents and gaining complete operational control, etc., would be one of the major goals of the manufacturers this year.

More Transparent Production-

Consumers are increasingly interested in knowing about the items they purchase than ever before due to increased concerns about food safety, ethical sourcing, data security, and environmental impact.

“According to research, 94% of consumers are more likely to be loyal to a brand that offers complete supply-chain transparency, while 39% say they’re willing to switch to a more transparent brand.”

As a result, manufacturers will seek to implement robust tracking capabilities across their supply chains. Thus, from inception to consumption, 100% transparency will be a prominent trend this new year.

Prioritizing Quality Culture-

For a successful quality management program, quality culture is of paramount importance.

People often consider that only records, SOPs, and documentation, govern the ideology of “quality.” However, these factors account for 20–30% of maintaining quality.

The quality culture and mentality that you introduce within the organization will ensure that individuals truly adhere to the SOPs, comprehend them, and internalise them.

Hence, in 2024, instilling a culture of quality by deploying a good quality management software that allows the user to do the job right, will be a trend.

Making data-driven decisions-

What separates a thriving business from a declining one is the quality of decisions the management makes. And data proves to be the key to sound decisions.

For this, having a QMS software that offers robust functionalities like real-time view and operational insights of the business, helps manufacturers make data-driven decisions.

More Effective Training Programs-

A successful quality management program not only depends on improving processes using Quality Management Systems, but also enhancing involvement of and upskilling employees.

Hence, to accomplish the goal of delivering high-quality products and services, businesses need to invest in building effective training programs for their employees to reduce the possibilities of error— thus fixing a place in the top trends this year is Training Programs.

Better Audit Preparedness-

With an increase in globalization and technology, the manufacturing sector has become more vulnerable to the risks. Moreover, with time, even the norms and norm-makers have become stringent and stricter.

That said, performing manufacturing audits actually help identify the gaps, gain useful business insights, and improve company’s future performance.

And staying ready for such audits is not just a trend but a good business practice.

A Comprehensive Solution-

The world is coming on a platform called technology. Integrated solutions are the norm. We agree that best-of-breed software have better capabilities, but they come with a potpourri of drawbacks-

- 1. Inconsistent workflow

- 2.Increased time in integrating data

- 3. Extra cost due to multiple implementations & maintenance

- 4. Disconnected and spilled data 5. Errors and lag in data retrieving

An integrated solution, quite like a QMS with all-essential modules, on the contrary keeps the entire organization on a common platform.

It provides real-time, unified, and precise data without the need for uploads and downloads. These benefits have won a place for an integrated and unified QMS Software in prominent trends this year.

Final Words-

Though the impact of the above-mentioned trends could be different for different organizations but, making the right choice of the solution would be the defining factor in terms of growth & productivity.

One such solution that proves competent to all the quality management requirements even during the changing market trends is the QualityMaster.

Being a next-generation, cloud-based software, it helps manufacturers streamline the key quality management processes—ensuring quality throughout the product lifecycle.